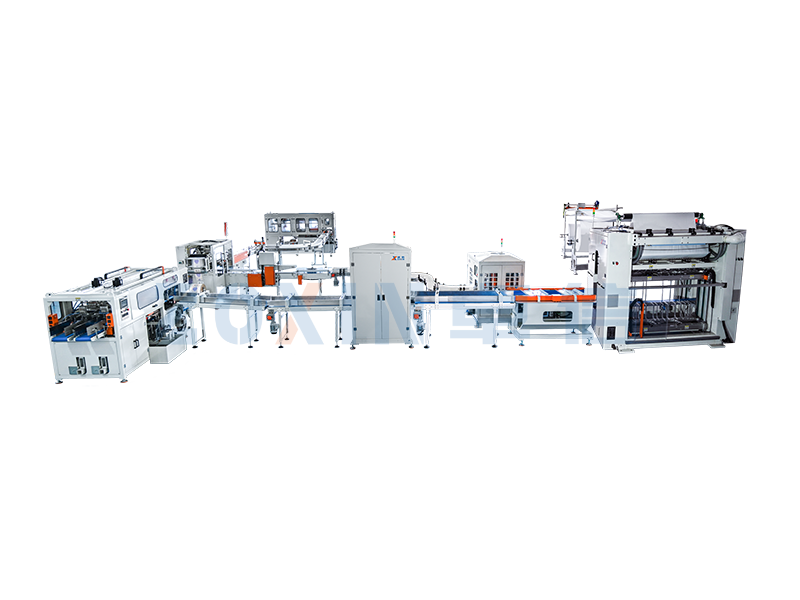

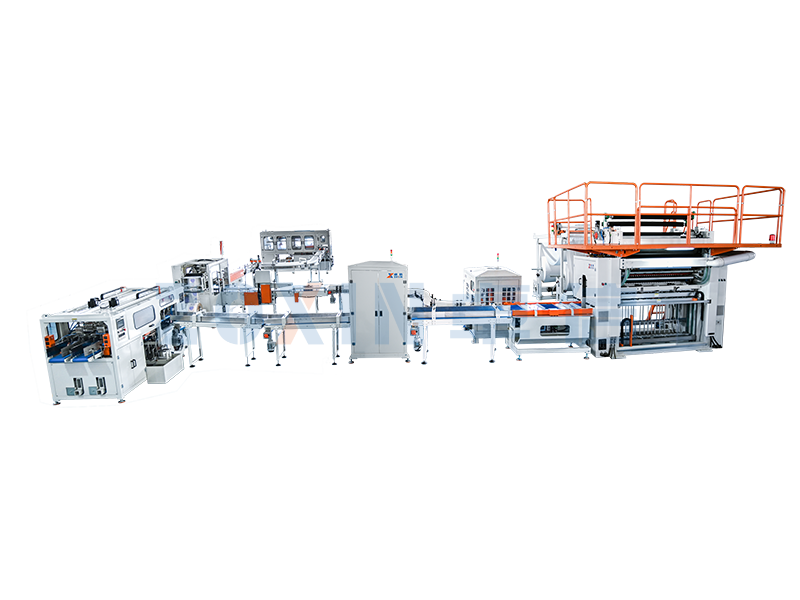

Fully automatic extracting facial tissue three-dimensional packaging machine

1. 17 sets of closed-loop servo motor control, 20-axis linkage operation; high control precision and strong stability.

2. Electrically controlled film unwinding and correction, knife holder lifting and lowering, and output height adjustment, greatly improving the convenience of specification changes.

3. Laser detection of film tension ensures precise film unwinding and flatness, improving coding clarity and cutting accuracy.

4. Intelligent material detection: Automatic start of equipment operation upon material arrival, reduced equipment operating speed during no-material conditions to reduce energy consumption and equipment wear.

5. Convenient and intelligent operation procedures, comprehensive monitoring of abnormal situations: overload protection, shutdown alarm; one-button start after clearing abnormalities.

6. Vacuum suction film unwinding: Effectively improves the flatness of paper and film contact.

Keywords:

Zhuoxin Automation

Category:

Facial tissue production line solution

Full-function extraction paper towel production line

Fully automatic extracting facial tissue three-dimensional packaging machine

Full-function extraction facial tissue production line (four-sided embossed style)

Fully automatic extracting facial tissue three-dimensional packaging machine

Fully automatic extraction type facial tissue production line

Fully automatic extraction facial tissue production line (four-side embossed)

Fully automatic extracting facial tissue three-dimensional packaging machine

Fully automatic extracting facial tissue three-dimensional packaging machine

Hotline:

Product description

Product Parameters:

| Equipment Name | Fully Automatic Extraction Type Facial Tissue 3D Packaging Machine | ||||

| Equipment Model | ZX-S200 | ||||

| Equipment Dimensions | L3600mm×W950mm×H1750mm | ||||

| Production Product Dimensions | Length 90-230mm Width 85-110mm Height 25-120mm | ||||

| Packaging Material | Double-sided heat-sealable film (CPP) | ||||

| Production Speed | 200 bags/minute | ||||

| Packaging Method | Three-dimensional wrapping | ||||

| Heating Power (KW) | 4600W | ||||

| Main unit input voltage/power | 380V/18KW | ||||

| Working air pressure | 0.6-0.8 (requires self-provision) | ||||

| Overall weight | 2500Kg | ||||

| Power mode | Full servo bus drive (Inovance) | ||||

| Parameter Setting Method | Full-size Inovance industrial control screen control, touch screen real-time adjustment | ||||

Previous page

Related products

Leave a message

Please fill in your relevant information! We will give you a satisfactory quotation!